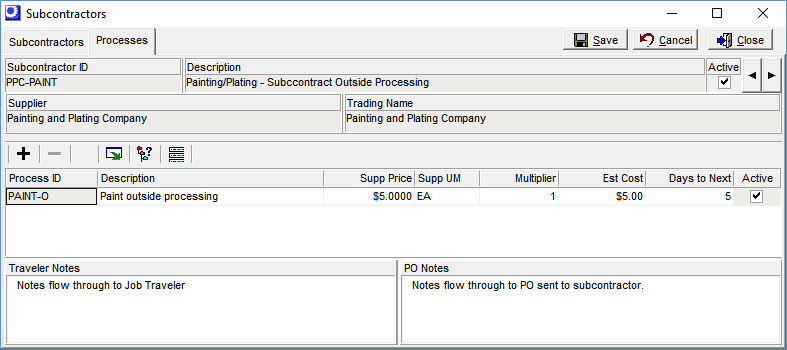

(BOM – Subcontractors - Processes Tab)

On this tab you set up commonly performed “processes” that are performed by this subcontractor. Processes are used to originate new subcontract routing sequences within the Bills of Material and Jobs screens.

Link:

Startup Guide - Subcontractor Processes

Startup Guide - Subcontractor Processes

Processes are not required

You are not required to define specific processes at each Work Center. It is OK to use the DEFAULT process for each Subcontract Work Center and you then define your Routing sequences from scratch in each respective BOM.

Potential Benefits of Using Processes

Instead of creating each routing from scratch, creating a set of common processes makes it easier and faster to create new routings. You simply select a process from the lookup, or a set of sequential processes using the Routing Generator, to create routing sequences. Once the sequence is created, its description, supplier price, job traveler notes, or PO notes can be edited as needed to suit the particular service to be performed.

Screen Details

Upper Panel

Subcon Work Center ID, Description, Active, Supplier, Trading Name

These read-only fields identify the subcontract work center.

◄ ►

Click these buttons to select the previous subcontract work center listed on the Subcontractors tab or to advance to the next subcontract work center.

Buttons

+

Click this button to add a process to the grid below.

–

Click this button to delete a process.

NOTE: This button is grayed out if the process is assigned to an existing BOM or job routing sequence. As an alternative to deletion, clear the Active checkbox against the process.

Output Grid

Click this button to launch the Grid Output screen. Buttons in the upper panel of that screen enable you to output the grid contents to an Excel spreadsheet, an HTML file, a CSV file, or to a printout.

Process Where Used

Click this button to launch the Subcontractor Process Where Used inquiry, which provides a listing of the routing sequences to which the selected process is assigned.

BOM Mass Update

Click this button to launch the BOM Sequence Mass Update screen, which enables you to apply subcontract process settings changes to all BOM routing sequences assigned to this process.

Screen Details

Upper Panel

This subcontract process’s settings are listed in this panel. These settings will be applied to all BOM sequences listed in the grid against which the Update checkbox is selected.

Middle Panel

Display Descriptions

Select this checkbox to display descriptions in the grid for the BOM Parent, Revision, and Sequence.

Update Button

Click this button to apply this process’s settings to all BOM sequences listed in the grid against which the Update button is selected.

Grid

Update

This checkbox is selected by default, but you can clear it against any BOM process that you do not want updated.

Grid Fields

Process ID

Enter an up to 20-character alphanumeric code that identifies the process on lookups, screens, and reports.

DEFAULT Process

At least one process must be assigned to each subcontractor. If you add a new subcontractor and save it without creating at least one process, the program will automatically create a process with an ID of ‘DEFAULT’. If you choose not to use processes, the DEFAULT process will be used to originate all new routing sequences for this subcontractor. If you use processes, you can delete the DEFAULT process and enter your own set of processes.

Description

Enter an up to 50-character description of the process to be performed.

Supp Price

This is the price charged by the supplier for the subcontract service.

Supp UM

This is the supplier’s unit of measure, which may differ from your unit of measure. For example, a heat-treater might charge you by the pound or kilo for pricing purposes, but that price is translated (using the Multiplier) into the Est Cost, which conforms to the BOM parent’s unit of measure.

Multiplier

If the Supp Price and Est Cost have different units of measure, the Multiplier is used to translate the Supp Price into an Est Cost, using this formula:

Supp Price * Multiplier = Est Cost

NOTE: This field is given a value of ‘1’ by default.

Calculating the Multiplier

To calculate the multiplier value, use this formula:

Supplier Qty / Your Qty = Multiplier

For example, let’s say the BOM parent weighs 10 pounds and the supplier prices the subcontract service by the pound. Using our formula, the multiplier would be ‘10’, as follows:

10 lbs / 1 BOM Parent = 10

Est Cost

This is the estimated cost that is used by the Cost Rollup to help calculate the total estimated cost for the BOM parent. It is calculated by the program as follows:

Supp Price * Multiplier = Est Cost

Days to Next

This is the number of days it takes to get the items sent out and received back from the supplier.

Active

Clear this checkbox to inactivate the process. This removes the process from lookups and the Routing Generator so that it is no longer available for new routing sequence creation.

NOTE: You are not permitted to clear this checkbox when the process is assigned to a routing sequence associated with a current or pending BOM revision.

Traveler Notes

The notes entered here print on the job traveler. These notes are for shop personnel and are not passed over to the PO that ultimately gets generated for this subcontract service.

PO Notes

The notes entered here get passed into the PO that ultimately gets generated for this subcontract service. These notes do not print on the job traveler.