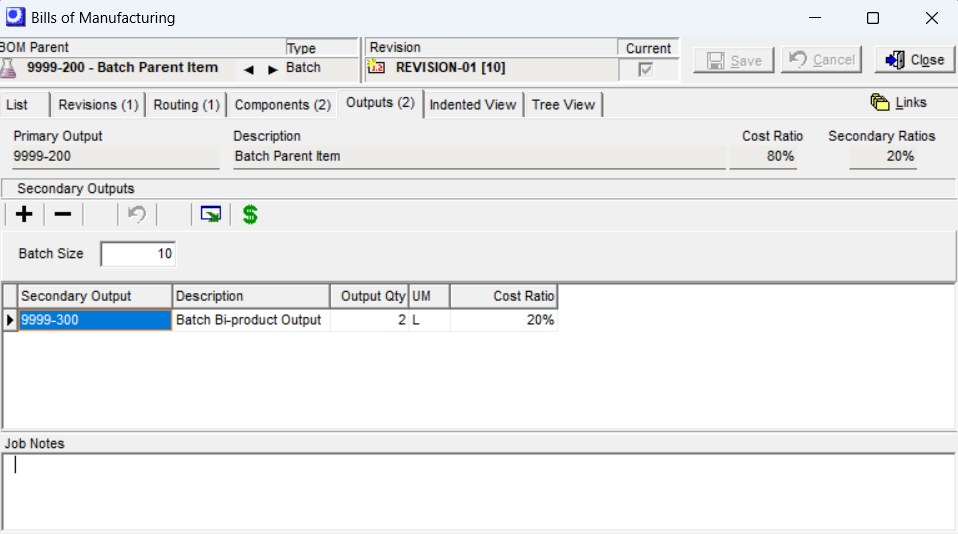

(BOM – Bills of Manufacturing - Outputs Tab)

Use this screen to enter “secondary outputs”, which are by-products, co-products, disassembled items, or usable scrap that gets derived while manufacturing the BOM parent.

Link:

Bill of Manufacturing Guide - Outputs

Bill of Manufacturing Guide - Outputs

MRP Tip

Secondary outputs are not subject to MRP generation

Secondary outputs are not subject to MRP generation. MRP only responds to the net demand associated with the primary output. So if you have two co-products that share the same BOM, use the one with the greatest demand as the primary output (BOM parent).

This means that you may have to apply manual planning to some secondary outputs. For example, you may wish to attach a review note in the MRP Settings screen to the primary output item that reminds you to check demand for its secondary outputs so that you can increase the planned job quantity if needed.

Screen Details

Upper Panel

Primary Output

The BOM parent is referred to as the “primary output” when jobs are originated from this BOM.

Description

The BOM parent’s description is displayed for reference.

Cost Ratio

This is the primary output’s percentage share of the BOM’s estimated cost as well as its percentage share of estimated and actual job cost for jobs originated from this BOM. The program calculates this value using this formula:

100 - Secondary Ratios = Cost Ratio

Secondary Ratios

This is the sum of the Cost Ratio values in the Secondary Outputs grid.

Buttons

+

Click this button to add a secondary output. Two options are available:

Secondary

Select this option to lookup BOM parents with a Type of Secondary.

NOTE: MRP does not generate Jobs for Secondary Outputs demand

MRP will not consider stock shortages for secondary items and can only generate Jobs for the primary output item in response to demand

Stock Item

Select this option for a lookup listing of stock items. This will allow you to define a standard purchase item or subassembly item as an output. Phantoms, CTO items, and One-Off Items are excluded.

.

–

Click this button to delete a secondary output.

Undo

Click this button to “undo” any screen entries that have not yet been saved.

Output Grid

Click this button to launch the Grid Output screen. Buttons in the upper panel of that screen enable you to output the grid contents to an Excel spreadsheet, an HTML file, a CSV file, or to a printout.

$ Icon

Click this button to access the BOM Outputs Cost Inquiry (see documentation below). This will only be visible for the Current Revision where there are one or more secondary outputs defined.

Grid Header

Batch Size

This field is only visible when the BOM parent has a Type of ‘Batch’. The batch size associated with this revision is displayed for reference when entering output quantities.

Grid Fields

Secondary Output

This field identifies the secondary output.

Description

The secondary output’s description (from the Stock Items screen) is displayed for reference.

Output Qty

The output quantity depends on the BOM type.

| • | If the BOM parent has a type of ‘BOM’, enter the output quantity associated with one unit of the primary output. |

| • | If the BOM parent has a type of ‘Batch’, enter the output quantity associated with the primary output’s batch size. |

UM

The secondary output’s stocking unit of measure is displayed for reference.

Cost Ratio

Enter the secondary output’s relative share of overall cost, using your “best guess” estimate. The cost ratio is used by the Cost Rollup and Job Receipts screens to allocate total cost to each output.

NOTE: When you enter a cost ratio, the primary output’s cost ratio is adjusted so that the sum of all cost ratios equals ‘100’.

Job Notes Panel

You can enter freeform text in this notes field. This text is passed into the Line Notes associated with job detail lines created from this BOM.

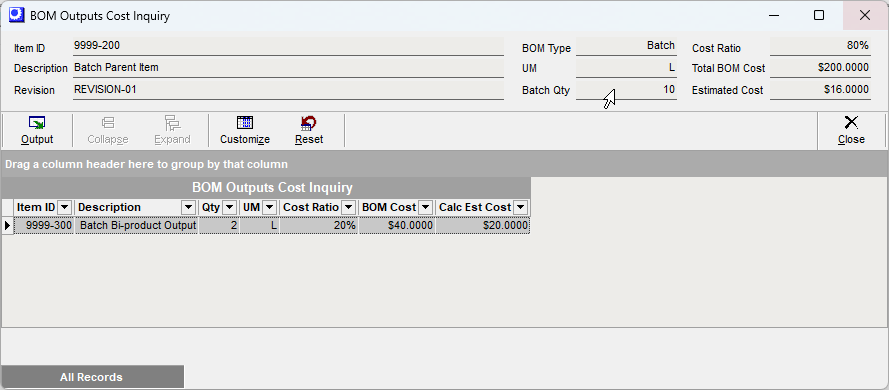

BOM Outputs Cost Inquiry

Header Fields

Cost Ratio

This is the primary output’s percentage share of the BOM’s estimated cost as well as its percentage share of estimated and actual job cost for jobs originated from this BOM. The program calculates this value using this formula:

100 - Secondary Ratios = Cost Ratio

Total BOM Cost

This is the total cost for the Batch Qty. Standard BOMs the Batch Qty = 1.

Estimated Cost

This is the unit Estimated Cost for the parent Item ID. The program calculates this value using the following formula:

(Total BOM Cost x Cost Ratio of Parent ID) / Batch Qty

Grid Fields

Item ID, Description

Item ID and description of secondary output

Qty, UM

This is the Qty and UM of the secondary output. Note: this quantity can differ from the Primary Output quantity.

Cost Ratio

This is the percentage share of costs attributed to this secondary output.

BOM Cost

This is the portion of the Total BOM Cos of the batch apportioned to the secondary output. The program calculates this value using this formula:

Total BOM Cost of Batch x Cost Ratio of Secondary Output

Calculated Est Cost

This is the unit cost est cost for the secondary output. The item master Est Cost for secondary outputs are managed in the BOM > Estimated Secondary Costs screen. The program calculates this value using this formula:

BOM Cost / Qty of Secondary Output