Shop Rates

(BOM – Shop Rates)

Use this screen to update an hourly shop rate for direct labor and an hourly shop rate for manufacturing overhead. These shop rates are applied to work center hourly rates, where they can be factored up or down for exceptions.

What is the purpose of the Shop Rates screen?

The purpose of the Shop Rates screen is to maintain a single shop hourly rate for direct labor and a single shop hourly rate for manufacturing overhead. The hourly shop rates get applied to work center hourly rates where they can be factored up or down for exceptions.

What are the benefits of the Shop Rates screen?

Self adjusting shop rates are a true DBA innovation. The overall goal of the costing system is for your absorbed costs for labor and manufacturing overhead to offset your actual payroll costs for your production workers and your actual costs for your manufacturing overhead. Many competing systems attempt to tie down their payroll hours with job reported hours. Matching hours to hours is nearly impossible to do and does not lead to more accurate absorbed costs. You run into major problems addressing the following common issues: attempting to track non production time (down time), handling partially attended sequences, accommodating workers that can run more than one sequence at a time, handling labor for rework, the requirement for perfect accuracy of your cycle times, etc.

Instead of worrying about payroll hours, DBA takes your overall costs for a given period of time and compares that to the production hours reported for that same period of time. The strength of our approach is that you do not have to attempt to perfectly match your reported hours with actual clock hours. You can use Standard completion hours for reported time and the self calculated shop rate will automatically adjust accordingly. The end result will be that you will achieve reasonably accurate absorbed labor and manufacturing overhead costs without the need to be perfect in your labor time tracking.

How are shop rates determined?

The two shop rates are calculated using the following formulas from a recent date range of actual costs and reported labor hours. This enables future job labor transactions to be costed at hourly labor and overhead rates that fully absorb your actual costs into work in process, which ultimately flows into inventory value and cost of goods sold.

Actual Direct Labor Costs / Reported Job Hours = Shop Labor Rate

Actual Mfg Overhead Costs / Reported Job Hours = Ship Overhead Rate

What are direct labor costs?

Direct labor costs are the actual payroll costs associated with production worker employees, including benefits, taxes, and wages, as well as their share of workmans compensation insurance. Contract worker costs are also direct labor costs.

NOTE: Do not include payroll costs for manager, supervisor, shipping, receiving, warehouse, inspection, maintenance, and development employees, which are considered to be indirect labor costs.

What is the Absorbed Labor account?

The Absorbed Labor cost account gets updated by job labor transactions and is a contra-account that offsets actual direct labor costs over a given period of time. Absorbed Labor ideally washes out with actual direct labor costs so that there is no effect on current net income. Instead, absorbed labor costs flow from work in process into item inventory costs and only affect net income in the form of Cost of Goods Sold when items are invoiced.

The objective of the Shop Rates screen is to calculate a shop labor rate that enables Absorbed Labor to wash out with actual direct labor costs.

What is manufacturing overhead?

Manufacturing overhead includes all the indirect costs associated with the manufacturing process, including the factory’s share of rent, utilities, maintenance, supplies, taxes, insurance, and depreciation, as well as payroll benefits, taxes, and wages for indirect labor, which includes shop manager, supervisor, shipping, receiving, warehouse, inspection, and maintenance employees.

NOTE: Manufacturing overhead should not include selling, general and administrative (SG&A) expenses.

What is the Absorbed Mfg Overhead account?

The Absorbed Mfg Overhead cost account gets updated by job labor transactions and is a contra-account that offsets actual manufacturing overhead costs over a given period of time. Absorbed Mfg Overhead ideally washes out with actual manufacturing overhead costs so that there is no effect on current net income. Instead, absorbed manufacturing overhead costs flow from work in process into item inventory costs and only affect net income in the form of Cost of Goods Sold when items are invoiced.

The objective of the Shop Rates screen is to calculate a shop overhead rate that enables Absorbed Mfg Overhead to wash out with actual direct labor costs.

Income statement example

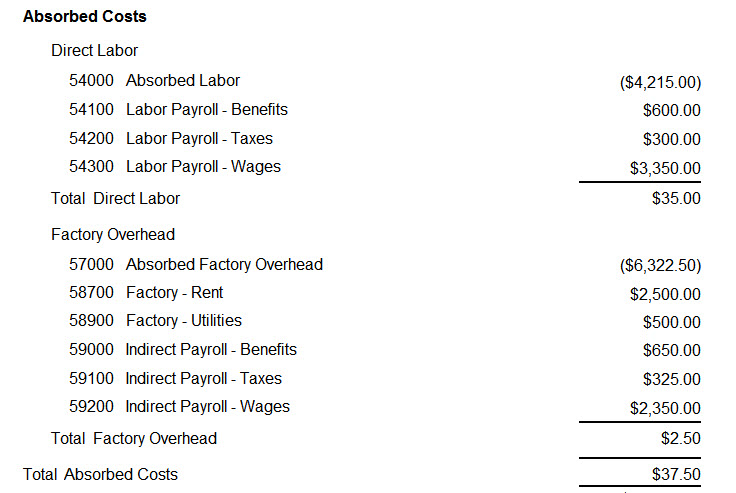

It may help you conceptualize how absorbed costs wash out with actual costs by reviewing the following Cost of Sales - Absorbed Costs section of a sample income statement.

NOTE: Keep in mind that this is simplified sample data and that in a real company many more actual cost accounts will be displayed, especially in regards to manufacturing overhead costs.

Direct Labor Section

Take note of the Direct Labor section of the income statement. Job labor costs within this date range are posted to the Absorbed Labor account based on the shop labor rate applied to work center hourly rates. The objective of the hourly shop labor rate is for total Absorbed Labor to roughly offset the adjacent actual direct labor cost accounts, which neutralizes any effect on cost of sales. Job labor costs get absorbed into item inventory values with job receipts and ultimately affect cost of sales through cost of goods sold when items are invoiced.

Factory Overhead Section

Take note of the Factory Overhead section of the income statement. Job overhead costs within this date range are posted to the Absorbed Factory Overhead account based on the shop overhead rate applied to work center hourly rates. The objective of the hourly shop overhead rate is for Absorbed Mfg Overhead to roughly offset the adjacent actual overhead cost accounts, which neutralizes any effect on cost of sales. Job overhead costs get absorbed into item inventory values with job receipts and ultimately affect cost of sales through cost of goods sold when items are invoiced.

The recent past is used to predict the near future

Shop rates are calculated from recent past data, which provides a reasonable prediction of future hourly rates because the near future is likely to resemble the recent past. By default the screen displays reported job hours for the past three complete months. When you use the financial transfer accounting configuration, you will manually enter total direct labor costs and total manufacturing overhead costs from your outside general ledger for the same time period.

We recommend quarterly updating

We recommend updating shop rates once a quarter. If you recently implemented DBA and are still refining your numbers, you may wish to update shop rates more frequently, such as each accounting period, until they stabilize.

Variances are normal and expected

Because hourly shop rates are a prediction of future costs and hours, there will always be an accounting variance between absorbed costs and your actual labor and overhead costs. Such variances are normal and expected and are automatically handled by the accounting system.

Screen Details

Refer to the screen help for screen details.

Link:

Advance Setup

Labor and manufacturing overhead costing is handled completely differently in a manufacturing chart of accounts than in a generic chart of accounts.

Generic Chart of Accounts

In a generic chart of accounts, labor and manufacturing overhead costs are handled by Expense accounts and shop expenses are often blended with general expenses. For example, payroll expenses for shop and office employees are often lumped together into shared expense accounts. Shop and office expenses for rent, utilities, insurance, maintenance, utilities and other costs are often lumped into shared expense accounts.

Manufacturing Chart of Accounts

By contrast, in a manufacturing chart of accounts, labor and manufacturing overhead costs are handled by Cost of Sales accounts. Shop-related costs are isolated from general and administrative costs. Job labor and manufacturing overhead transactions post to contra-accounts that offset actual costs and thus “absorb” labor and overhead costs into the inventory costs of the items you make.

You must restructure your labor and overhead accounts

To use your chart of accounts with financial transfer processes, you must restructure your labor and manufacturing overhead accounts to convert your generic chart of accounts into a manufacturing chart of accounts.

Labor and Overhead Accounts Setup

If you have not yet structured your chart of accounts to isolate direct labor and manufacturing overhead accounts as Cost of Sales accounts, refer to the following chapter in the Financial Transfer guide for setup details.

Link: