(Sales – Late Supply)

This screen is used to track sales order line items that are dependent on late supply from jobs and purchase orders. The screen enables direct updating of line item Expected Ship dates to reflect likely ship dates based on feedback from production, purchasing, and MRP.

Related Video:

Training Guide - Managing SO Dates

Training Guide - Managing SO Dates

Provides feedback from production

The production department maintains the Job Finish date against released jobs in the Job Schedule screen, which reflects an assessment of when the job is likely to be finished. When a job has dependent sales order line items (where the Job Finish date is past the line item Required Date), those sales order line items are listed in the Late Supply screen on the Jobs tab.

Provides feedback from purchasing

The purchasing department maintains the Expected Receipt date against PO lines in the PO Schedule screen, which reflects when the purchased item is likely to be received. When a PO line has dependent sales order line items (where the Expected Receipt date is past the line item Required Date), those sales order line items are listed in the Late Supply screen on the POs tab.

Provides stocking item feedback from MRP

After each MRP session the Late Supply screen can be filtered for New status jobs that supply Stocking order policy line items. Any such sales order line items are not fully covered by stock on hand and will be shipped late.

Enables direct updating of expected ship dates

The Late Supply screen enables direct updating of sales order line item Expected Ship dates to reflect feedback from production, purchasing, and MRP and to provide communication dates for customers.

NOTE: Unlike the line item Required Date, which is an internal target date that remains fixed because of its effect on MRP and job and picking priority, the line item Expected Ship date is an external date for customer communications and can be freely changed as needed.

SO lines not listed are supplied on time

The Late Supply screen is an exception screen that only lists sales order lines that are dependent on late supply from jobs or purchase orders. All other sales order lines are supplied on time and their Expected Ship dates can be left as is.

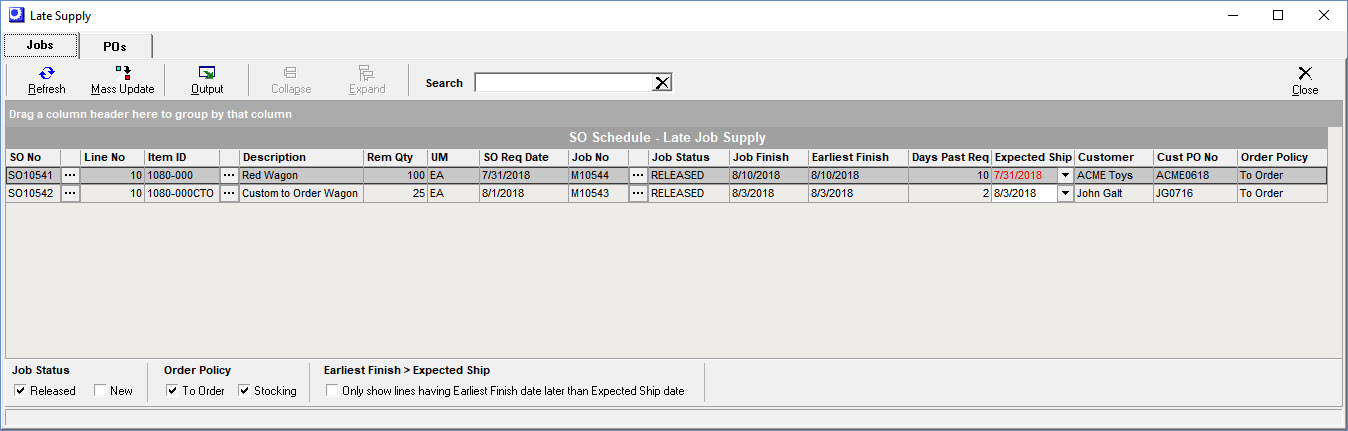

Jobs Tab

This tab lists sales order lines that are dependent on jobs scheduled to be finished past the line item required date.

Buttons

Refresh

Click this button to re-load the grid and to apply filter selections made in the lower panel.

Mass Update

Use this process to forward schedule the Expected Ship date equal to the Earliest Finish date for all sales order lines currently displayed in the grid.

Output

Click this button to output the grid contents to a spreadsheet. The output tool includes a variety of filtering and sorting options.

Collapse

When the grid is grouped by a column heading dragged into the upper panel, click this button to collapse the group contents.

Expand

When the grid is grouped by a column heading dragged into the upper panel, click this button to expand the group contents.

Search

Use this field to enter a search string, which limits the grid to sales order lines containing that string in any of the following fields – SO No, Job No, Item ID, Description, Customer, Cust PO No.

Drag & Drop Panel

You can drag and drop any column heading into the header panel to group lines by the field values in that column. You can also drag and drop an additional column heading to create a sub-group.

Grid Fields

SO No, Line No, Item ID, Description

These fields identify the sales order line item.

Rem Qty, UM

These fields are the remaining quantity, which is the order quantity less the quantity picked to date, and the item’s unit of measure.

SO Req Date

This field is the line item Required Date, which remains as is because it determines job and picking priority.

Job No

This field identifies the job that supplies this line item. If the line item is supplied by multiple jobs, this is the job with the greatest Days Past Req value.

Job Status

This field displays the job status, which can be New or Released, depending on the Job Status checkbox selection in the lower panel. Released job status is selected by default.

New status jobs impact stocking items

New status jobs are not yet in live production and are of no concern for To Order policy items. When a New status job supplies a Stocking order policy item, the item does not have sufficient stock on hand for immediate shipment. After each MRP session we recommended limiting the screen to New status jobs and Stocking order policy items to identify such line items so that customers can be notified of the late ship date.

Job Finish

This is the planned Job Finish date, which is maintained in the Job Schedule screen.

Earliest Finish

This is the earliest calculated job finish date, which is based on three possible conditions:

•When the job status is New and the planned Start Date is in the past, this date is forward scheduled from the current date, maintaining the shop days spread between job start and job finish.

•When the job status is Released and the Job Finish date is in the past, this is the current date.

•Otherwise, this date is the same as the Job Finish date.

Days Past Req

This is the number of calendar days that the Required Date will be past due relative to the Earliest Finish date.

Expected Ship

This is the line item Expected Ship date, which reflects your assessment of the likely ship date. It is the customer communication date and can be freely changed without affecting job or picking priority. To change the date, click the down arrow and use the entry form to select the new date.

Customer

This field identifies the customer associated with this sales order.

Cust PO No

This field identifies the customer purchase order number associated with this sales order.

Order Policy

This field identifies this item’s current order policy, which can be To Order or Stocking.

Filter Panel

Job Status

These checkboxes enable the grid to be filtered by job status.

Released

This status is selected by default because Released status jobs are in production and have a direct impact on dependent sales orders.

New

This status is not selected by default because New status jobs are not in production and do not have an immediate impact on dependent sales orders. This filter is typically used to identify Stocking order policy line items that do not have sufficient stock on hand for immediate picking.

Order Policy

These checkboxes are used to filter the screen by order policy.

To Order

Items with a To Order policy are planned to always be made to order.

Stocking

Items with a Stocking order policy are planned for immediate shipment from stock on hand. When such items are listed in this screen, stock on hand is not available as planned and the late item is dependent on supply from the job in progress.

Earliest Finish > Expected Ship

Select this checkbox to limit the screen to sales order lines where the Earliest Finish date is past the Expected Ship date.

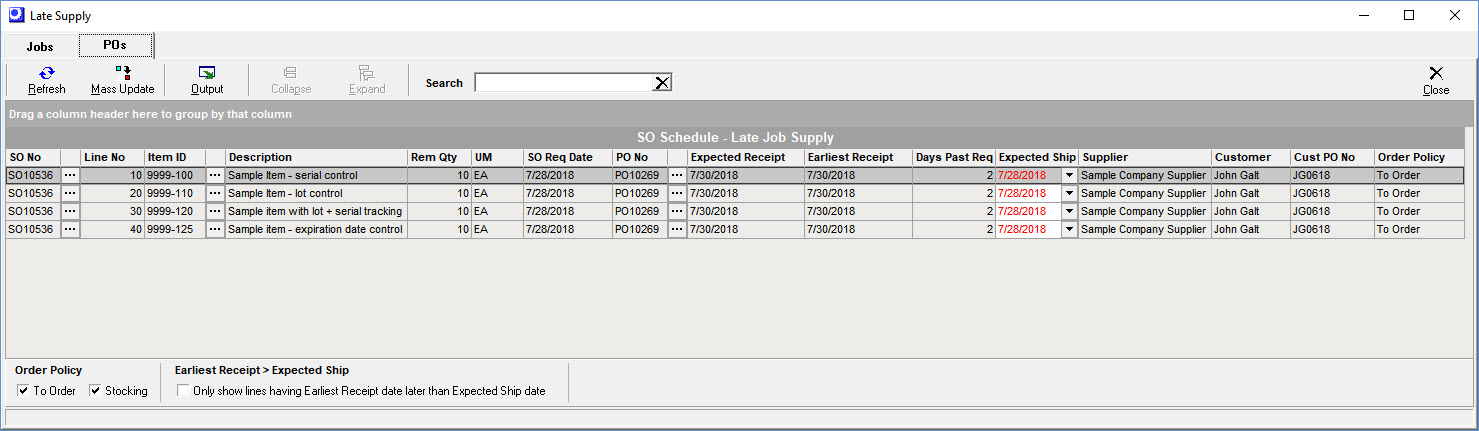

POs Tab

This tab lists sales order lines that are dependent on purchase orders scheduled to be received past the line item required date.

Buttons

Refresh

Click this button to re-load the grid and to apply filter selections made in the lower panel.

Mass Update

Use this process to forward schedule the Expected Ship date equal to the Earliest Receipt date for all sales order lines currently displayed in the grid.

Output

Click this button to output the grid contents to a spreadsheet. The output tool incudes a variety of filtering and sorting options.

Collapse

When the grid is grouped by a column heading dragged into the upper panel, click this button to collapse the group contents.

Expand

When the grid is grouped by a column heading dragged into the upper panel, click this button to expand the group contents.

Search

Use this field to enter a search string, which limits the grid to sales order lines containing that string in any of the following fields – SO No, PO No, Item ID, Description, Supplier, Customer, Cust PO No.

Drag & Drop Panel

You can drag and drop any column heading into the header panel to group lines by the field values in that column. You can also drag and drop an additional column heading to create a sub-group.

Grid Fields

SO No, Line No, Item ID, Description

These fields identify the sales order line item.

Rem Qty, UM

These fields are the remaining quantity, which is the order quantity less the quantity picked to date, and the item’s unit of measure.

SO Req Date

This field is the line item Required Date, which remains as is because it determines picking priority.

PO No

This field identifies the purchase order that supplies this line item. If the line item is supplied by multiple purchase orders, this is the one with the greatest Days Past Req value.

Expected Receipt

This is the Expected Date for this PO line item, which is maintained in the PO Schedule screen.

Earliest Receipt

If the Expected Receipt date is in the past, this is the current date. Otherwise, it is the same as the Expected Receipt date.

Days Past Req

This is the number of calendar days that the Required Date will be past due relative to the Earliest Receipt date.

Expected Ship

This is the line item Expected Ship date, which reflects your assessment of the likely ship date. It is the customer communication date and can be freely changed without affecting picking priority. To change the date, click the down arrow and use the entry form to select the new date.

Supplier

This field identifies the supplier associated with this purchase order.

Customer

This field identifies the customer associated with this sales order.

Cust PO No

This field identifies the customer purchase order number associated with this sales order.

Order Policy

This field identifies this item’s current order policy, which can be To Order or Stocking.

Filter Panel

Order Policy

These checkboxes are used to filter the screen by order policy.

To Order

Items with a To Order policy are planned to always be made to order.

Stocking

Items with a Stocking order policy are planned for immediate shipment from stock on hand. When such items are listed in this screen, stock on hand is not available as planned and the late item is dependent on supply from the job in progress.

Earliest Receipt > Expected Ship

Select this checkbox to limit the screen to sales order lines where the Earliest Receipt date is past the Expected Ship date.