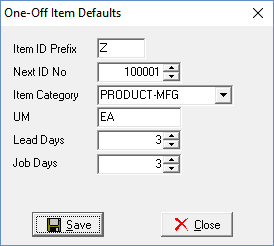

(Inventory – Inventory Setup – One-Off Item Defaults)

Use this screen to enter default settings for the One-Off Item Generator, which is used during sales order entry to create one-off items. One-off items are used to represent items that are made on a one-time basis or for service or repair jobs.

Screen Details

Item ID Prefix

All one-off items will be identified by this prefix, followed by a sequential number. The combination of the prefix and number constitutes the item ID that is used in sales orders, MRP, and jobs to identify the one-off item. Consider using a letter such as ‘Z’, which will keep your one-off items listed at the end of lookups and reports and keeps them from being intermingled with your permanent item IDs.

Next ID No

This displays the number that will be assigned to the next one-off item that gets generated. We recommend a beginning number of 100000.

NOTE: Do not start with a number such as ‘1’. If you do so, on reports and screen listings, ‘10’ will sort before ‘1’, ‘20’ before ‘2’, etc.

Item Category

All one-off items, when created, will be automatically assigned to this item category. We suggest you create a special item category solely for this purpose, perhaps also with an ID beginning with a letter such as ‘Z’ (i.e. Z-CUSTOM) to differentiate your one-off items from permanent stock items.

UM

All one-off items, when created, will be automatically assigned this unit of measure. At time of one-off item generation, you can override this default.

Lead Days

All one-off items, when created, will be automatically assigned this Lead Days setting for MRP planning purposes. At time of one-off item generation, you can override this default.

Job Days

All one-off items, when created, will be automatically assigned this Job Days setting for MRP planning purposes. At time of one-off item generation, you can override this default.