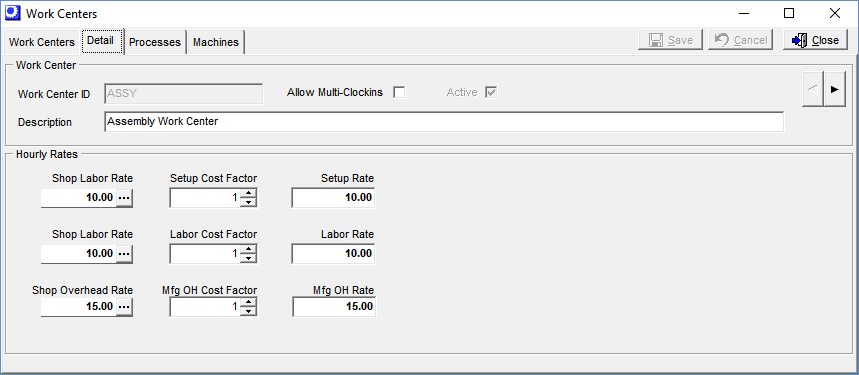

(BOM – Work Centers - Detail Tab)

Screen Details

Upper Panel

Work Center ID

Enter an up to 12-character code that identifies the work center on screens, lookups, and reports.

Allow Multi-Clockins

Select this checkbox if workers perform multiple jobs at the same time in this work center. This enables the entry of overlapping start and end times against a worker in the Job Labor screen.

Active

Clear this checkbox to inactivate the work center, which removes it from lookups.

NOTE: You are not permitted to clear this checkbox when the work center is assigned to a routing sequence associated with a current or pending BOM revision.

Description

Enter an up to 50-character description to accompany the work center on lookups.

◄ ►

Click these buttons to select the previous work center listed on the Work Centers tab or to advance to the next work center.

Hourly Rates

Link:

Startup Guide - Work Center Cost Factors

Startup Guide - Work Center Cost Factors

Shop Labor Rate

This is the current shop labor rate, which is the cost basis from which the work center setup rate is derived. You can click this button to launch the Shop Rates screen where you can view, calculate, and change shop rates.

Setup Cost Factor

This is a multiplier that is applied to the Shop Labor Rate to calculate the work center Setup Rate. It is given a default value of ‘1’, which makes the work center setup rate equal to the shop labor rate. If you wish to adjust the work center rate higher or lower than the shop rate, change this setting accordingly. For example, if you want the setup rate to be 25% higher than the shop labor rate, enter ‘1.25’.

Setup Rate

This field is calculated by the program using this formula:

Shop Labor Rate * Setup Cost Factor = Setup Rate

Shop Labor Rate

This is the current shop labor rate, which is the cost basis from which the work center labor rate is derived. You can click this button to launch the Shop Rates screen where you can view, calculate, and change shop rates.

Labor Cost Factor

This is a multiplier that is applied to the Shop Labor Rate to calculate the work center Labor Rate. It is given a default value of ‘1’, which makes the work center labor rate equal to the shop labor rate. If you wish to adjust the work center rate higher or lower than the shop rate, change this setting accordingly. In general, we recommend leaving the cost factor at the default value of ‘1’ unless you have one of the following examples..

Examples - Using Standard Hours and Labor Cost Factor

Partially attended Work Center

Some work centers can be loaded and run without needing a worker to be present the entire time. Lets say the Work Center is attended 20% of the time. You can set the labor factor to .20 and the Mfg OH to 1 and this will adjust the absorbed labor costs but still provide the full burden rate for overhead.

One worker operating multiple machines

A work center may consist of four machines that are operated simultaneously by one worker. If you want to cost labor in this work center at 1/4 of the shop rate, you would enter a cost factor of ‘.25’. You can leave the Mfg OH factor at 1.

Fixed Team at the Work Center

Conversely, the work center might be a machine that is run by a team of four workers. All sequences should be set to Standard hours type. If you want to cost labor in this work center to reflect the cost of this team, you would enter a cost factor of ‘4’.

Labor Rate

This field is calculated by the program using this formula:

Shop Labor Rate * Labor Cost Factor = Labor Rate

Shop OH Rate

This is the current shop overhead rate, which is the cost basis from which the work center overhead rate is derived. You can click this button to launch the Shop Rates screen where you can view, calculate, and change shop rates.

Mfg OH Cost Factor

This is a multiplier that is applied to the Shop OH Rate to calculate the work center Mfg OH Rate. It is given a default value of ‘1’, which makes the work center overhead rate equal to the shop overhead rate. If you wish to adjust the work center rate higher or lower than the shop rate, change this setting accordingly.

Example

A work center may consist of an expensive machine that occupies a larger share of floor space, consumes a higher share of electricity, and requires more maintenance than other work centers. In this case, you would enter a cost factor greater than ‘1’ (such as ‘1.5’ or ‘2’) to allocate a greater share of the overhead burden to this work center.

Mfg OH Rate

This field is calculated by the program using this formula:

Shop OH Rate * Mfg OH Cost Factor = Mfg OH Rate