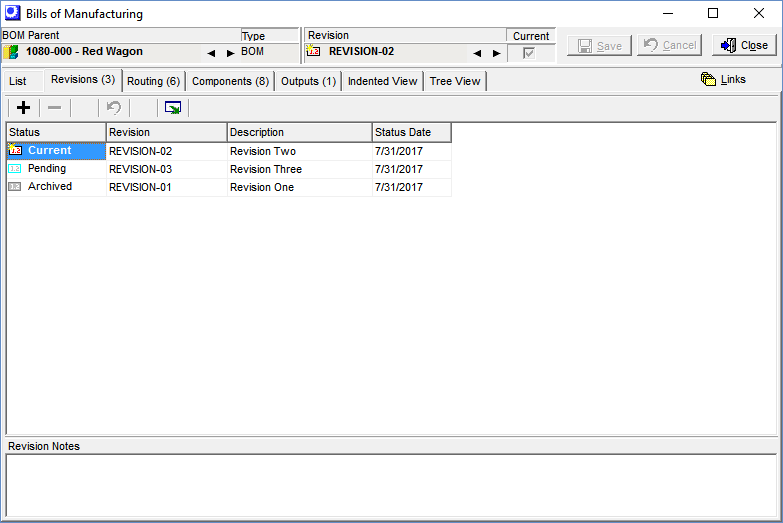

(BOM – Bills of Manufacturing - Revisions Tab)

BOM Revisions are managed in this tab.

Link:

Startup Guide - Revision Names

Startup Guide - Revision Names

Each BOM is assigned to a ‘current revision”, which represents the latest engineering specifications for the BOM parent. Revisions can be used two ways:

| • | If you don’t track revisions, you can maintain a single revision against which all future engineering changes are applied. |

| • | If you wish to track the engineering history of an item, you can create a new revision each time a major set of engineering changes is made. |

This tab governs the tab contents to the right

Each revision has its own routing and components. Whichever revision is selected in this tab determines the contents within the tabs to the right.

This tab is not visible for ‘One-Off’ and ‘Secondary’ BOM Types

Revisions do not apply to ‘One-Off’ or ‘Secondary’ BOM types, in which case this tab is not visible.

Do not use revisions to represent different products

Revisions should only be used to represent versions of the same product. Do not attempt to use revisions to represent different products using a common BOM parent. This will not work and causes problems with costing, MRP, and inventory.

There is only a single active revision for any manufactured item in the system.

MRP will always use the current active revision when generating Jobs. Revisions are not meant to represent different configurations of an item. Different variations of items should have different part numbers and BOMs.

Revision status is a linear progression

The revision in DBA is meant to have a linear progression from pending, to active to archived. You can work on new changes in a pending revision. When it is ready to go into production you will change the status of your pending revision to active and the old active revision will get changed to archived.

Perform a cost rollup after your change to a new Current revision

If there are any changes involved when you change to a new Current revision you should perform a BOM Cost Batch Rollup afterward. Cost Rollups will only be performed against the current active revision of a BOM.

Screen Details

Buttons

+

Click this button to add a new revision. You are presented with two options:

Copy Current Revision

The ‘Current’ status revision’s routing, component, and outputs specifications will be copied to the new revision name.

Create Revision from Scratch

The new revision will not have any routing, component, or output details, which will be entered from scratch.

–

Click this button to delete the selected revision.

Undo

Click this button to “undo” any screen entries that have not yet been saved.

Output Grid

Click this button to launch the Grid Output screen. Buttons in the upper panel of that screen enable you to output the grid contents to an Excel spreadsheet, an HTML file, a CSV file, or to a printout.

Grid Fields

Status

Three settings are available:

Current

One revision must be designated as the “current” revision. The routing, component, and output specifications associated with the current revision are used by MRP for job and PO generation.

Inactive

If the BOM parent is designated as ‘Inactive’ in the Stock Items screen, the current revision’s status changes to ‘Inactive’.

Pending

A “pending” revision will become the next current revision at a future date. A pending revision cannot be manufactured and is not available for MRP generation or selection in the Jobs screen.

Archived

This is an obsolete revision that cannot be manufactured and is not available for MRP generation or selection in the Jobs screen.

Revision

This is a 20-character alphanumeric field that identifies the revision.

Description

Enter an up to 50-character description that accompanies the revision on lookups.

Batch Size

This field is only visible on ‘Batch’ type BOMs. The batch size is used by process manufacturers (food, chemicals, plastics, etc.) where products are made according to a recipe or formula. Component usage quantities are defined against the batch size.

UM

This field is only visible on ‘Batch’ type BOMs. This is the stocking unit of measure for the BOM parent, as maintained in the Stock Items screen.

Status Date

Whenever a revision’s Status value gets changed, the date the change occurred is captured in this field for reference purposes.

Revision Notes

You can enter freeform notes against the revision selected above. When a job is generated from this revision, these notes are passed into the job header notes for optional printing on the job traveler.