(Jobs – Job Subcontracting)

Use this screen to generate POs for subcontract services (such as painting, plating, and heat-treating) that are performed during the course of jobs.

Link:

Training Guide - Job Subcontracting

Training Guide - Job Subcontracting

How are subcontract services defined in jobs?

Subcontract services are defined in the job Routing tab as a routing sequence, for scheduling purposes, and in the job Details tab as a job line, for purposes of PO generation in this screen. The job line gets created automatically when the routing sequence is created.

When are subcontract POs generated?

Unlike POs for purchased items, which are generated in advance of jobs, subcontract service POs are generated only when they are needed, which is during the course of the job when a job routing sequence alls for items to be sent out for outside processing.

How are subcontract Est Costs handled?

The Est Cost for subcontract services comes from the BOM Subcontract routing sequence. When you verify your pricing as you send out your subcontract POs, for signifianct changes you should update your Est Costs directly in the parent item BOM Subcontract Routing and then perform a BOM Cost Rollup to enact the change. Actively managing your Est Cost for your BOM Routing costs as you send out your subcontract POs will ensure your costing is in line with your expectations.

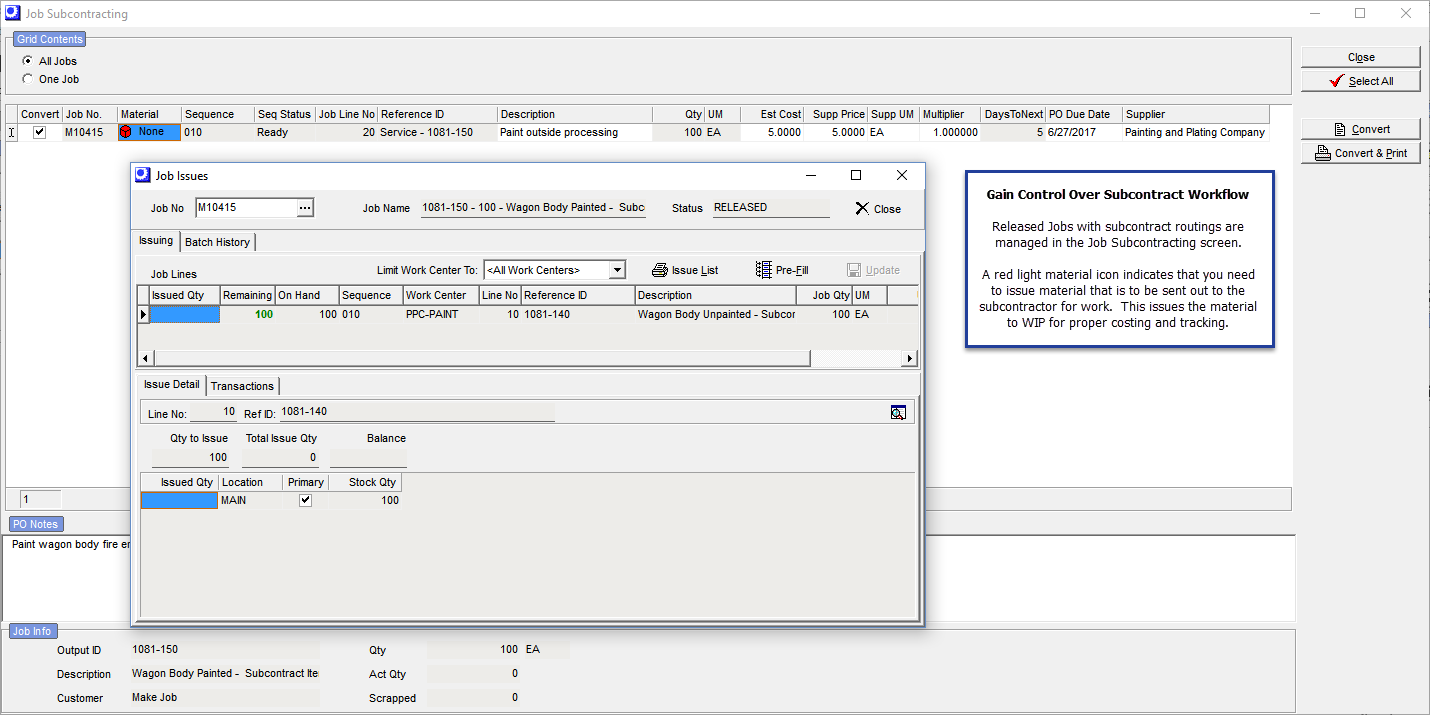

Subcontract Workflow

•Release the Job to production that includes a Subcontract routing

•Perform a Job Issue of the materials that you will be sending to the Subcontractor. This can be done from the Jobs > Job Subcontracting screen material icon.

•Go to Jobs > Jobs Subcontracting and generate the Subcon PO.

•Verify the pricing before sending out the PO. If the Est Cost changes significantly, you should go to the BOM > Bill of Manufacturing > Routing tab and update the Est Cost for this Subcontract routing. After the routing is updated, run a BOM>Cost Rollup to enact the change.

•Send the materials out with the Subcon PO. You can optionally use the Job Issues Dispatch report as a supporting document.

•The Subcontractor provides their services and returns the materials.

•Perform a PO receipt of the Subcon PO. This will issue the per unit subcontract costs to Work in Process for the parent Job.

•Complete the Job and perform a Job Receipt of the finished good output. The final output cost will include the subcontract costs.

Screen Details

Upper Panel

Grid Contents

All Jobs, One Jobs

| • | Select the All Jobs option to display all subcontract service job detail lines that have not yet been converted to POs. This option is selected by default when you launch this screen from the MRP menu. |

| • | Select the One Job option to limit the grid contents to job detail lines pertaining to the Job Number specified in the field that becomes visible at right. |

NOTE: If you link to this screen directly from the Job Control Panel screen, the One Job option is automatically selected for the job selected in the Job Control Panel.

Grid Fields

NOTE: Only job detail lines associated with ‘RELEASED’ status jobs are listed in the grid.

Convert

Select this checkbox if you wish to generate a PO line from this job detail line.

Job No

This identifies the job associated with this job detail line.

Material

This field indicates the status of job detail lines assigned to this sequence. Click the icon to launch the Job Issues screen, which is pre-filled with the job detail lines assigned to this sequence, as well as any job detail lines for previous sequences that have remaining quantities. The following values are displayed to indicate material status:

None

This value is displayed with a red icon and means that no job issue quantities have been made.

Some

This value is displayed with a yellow icon and means that some issue quantities have been made.

Review

This value is displayed with a green icon and means that issue quantities have been made, but one or more lines still has a partial quantity remaining to be issued.

All

This value is displayed with a green icon and means that issue quantities have been made and there are no partial quantities remaining to be issued.

Sequence

This identifies the routing sequence associated with this job detail line.

Seq Status

The sequence Status lets you know when the job detail line is ready for PO generation. Two values are relevant to this screen:

Open

This status tells you that PO generation is not needed at this time. ‘Open” status means that no receipts or completions have been reported to the sequence preceding this sequence.

Next

This status tells you that the item is ready or soon to be ready for PO generation. ‘Next’ status means that completions have been reported to the routing sequence preceding this sequence, which means that this sequence is the next one to be performed.

Job Line No

This identifies the line number associated with this job detail line.

Reference ID

Subcontract service line items created from routing sequences are identified by the word ‘Service’ followed by a dash and then the primary job output’s item ID. For example, a subcontract service performed on the red wagon in the sample company is given this reference ID:

Service - 1080-000

In the case of a descriptor detail line, this is the Descriptor ID.

Description

In the case of subcontract service line items created from routing sequences, the line item description is identical to the routing sequence description. In the case of descriptor line items, this is the descriptor’s description.

NOTE: Any change you make to this field value in this screen will also change this field value in the job detail line.

Qty

This is the job detail line quantity.

UM

This is the job detail line’s unit of measure.

Est Cost

This is the estimated cost in the job detail line that is used to help calculate the total estimated job cost. It is calculated by the program as follows:

Supp Price * Multiplier = Est Cost

NOTE: Any change you make to this field value in this screen will also change this field value in the job detail line.

Supp Price

This is the price charged by the supplier for the subcontract service. It is stored in the job routing sequence associated with this job detail line.

NOTE: Any change you make to this field value in this screen will also change this field value in the job routing sequence associated with this job detail line.

Supp UM

This is the supplier’s unit of measure, which is stored in the routing sequence associated with this job detail line. It may differ from the job detail line unit of measure. For example, a heat-treater might charge you by the pound or kilo for pricing purposes, but that price is translated (using the Multiplier) into the job line’s Est Cost and UM.

NOTE: Any change you make to this field value in this screen will also change this field value in the job routing sequence associated with this job detail line.

Multiplier

If the Supp Price and Est Cost have different units of measure, the Multiplier is used to translate the Supp Price into an Est Cost, using this formula:

Supp Price * Multiplier = Est Cost

Calculating the Multiplier

Normally the Multiplier is left as is, but you can change it in this screen if needed. To calculate the Multiplier value, use this formula:

Supplier Qty / Your UM Qty = Multiplier

For example, let’s say the job’s primary output weighs 10 pounds and the supplier prices the subcontract service by the pound. Using our formula, the Multiplier would be ‘10’, as follows:

10 lbs / 1 Each = 10

Days to Next

This field is stored in the job routing sequence associated with this job detail line. This amount is the number of days it takes to get the job items sent out, completed, and received back from the supplier.

NOTE: Any change you make to this field value in this screen will also change this field value in the job routing sequence associated with this job detail line.

PO Due Date

This is the date that will be used as the PO line’s Due Date when this job detail line gets converted to a PO line. This defaults to a future date based on adding the Days to Next to today’s date.

Supplier

This is the supplier that will be assigned to the PO generated from this job detail line and any other lines flagged for conversion for this supplier.

NOTE: Any change you make to this field value in this screen will also change this field value in the job detail line.

PO Notes

The PO Notes stored against the job routing sequence associated with the job detail line selected above is displayed in this freeform notes field and can be edited on this screen. These notes get passed into the PO line that gets generated from this job detail line.

NOTE: Any change you make to the notes here in this screen will also change the PO Notes in the job routing sequence.

Job Info Panel

This panel provides general information about the job associated with the job detail line selected above, including the job’s primary output, linked customer, and job quantity.

Buttons

Select All

Click this button to select the Convert checkbox on all lines listed in the grid.

Convert

Click this button to convert all lines with the Convert checkbox selected to PO lines. A single PO will be created for each supplier for all the line items assigned to that supplier. The following screen is presented in succession for each supplier so that you can specify a PO Type prior to each PO being created.

PO Detail Line

The following fields in each new PO line pertain to subcontract services:

Due Date

The Due Date specified in the Job Subcontracting screen is passed into the Due Date field in the PO line.

Subcon Job

The job number associated with the job detail line is passed into the Subcon Job field in the PO line. This links the PO line to its corresponding job detail line so that when the PO is received, the job line’s Act Qty and Act Cost values are automatically updated.

Sequence

The job routing sequence associated with the job detail line is passed into the Sequence field in the PO line. This links the PO line to its corresponding job routing sequence so that when the PO is received, the sequence’s completed quantity is automatically updated.

Notes

The PO Notes specified in the Job Subcontracting screen are passed into the PO line’s Notes.

Job Detail Line

The following field is updated in the job when the PO line is created.

Subcon PO

This field in the job detail line is populated with the new PO number, which links this line to the PO. The existence of a value ion this field is how the Job Subcontracting screen determines whether or not a PO line has been generated from the job detail line.

Convert & Print

Click this button if you wish to print out each PO as it gets created. The same processing described above for the Convert button still occurs, but after each PO is created, you are presented with the PO print preview screen, from which you can click the printer icon to print out the PO.