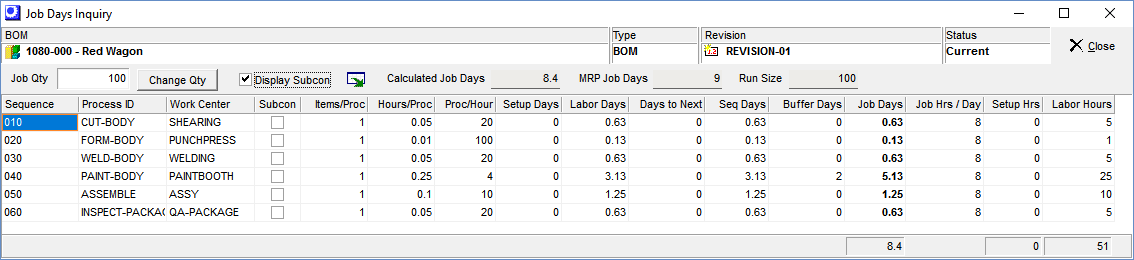

This inquiry calculates the estimated Job Days for an item based on current work center and routing settings. It is accessed from the Bills of Manufacturing, MRP Settings, and MRP screens.

Screen Details

Upper Panel

BOM, Type, Revision, Status

These fields identify the manufactured item.

Job Qty

This an entry field. When this inquiry is launched from the Bills of Manufacturing or MRP Settings screen, this defaults to the item's Run Size. When this inquiry is launched from the MRP screen, this defaults to the planned job Plan Qty. You can override the default value if you wish to apply a different quantity to the screen calculations.

Change Qty

Click this button to recalculate screen when a new Job Qty is entered..

Display Subcon

Clear this checkbox to remove subcontract routing sequences from the grid display.

Output Grid

Click this button to output the grid contents to a spreadsheet or text file.

Calculated Job Days

This is the sum of the Job Days column and is the total calculated job days required for making the Job Qty.

MRP Job Days

This field displays the item's current Job Days setting, which is maintained in the MRP Settings screen.

Run Size

This field displays the item's current Run Size setting, which is maintained in the MRP Settings screen.

Grid Fields

Sequence, Process ID, Work Center

These fields identify the job sequence.

Subcon

This checkbox identifies subcontract service sequences.

Items/Proc

This is the number of units produced by each process cycle.

Hours/Proc, Proc/Hour

These two fields represent the process cycle time.

Setup Days

These are the setup hours for this job sequence expressed in shop days, calculated as follows:

Setup Hours / Job Hrs/Day = Setup Days

Labor Days

These are the labor hours for this job sequence expressed in shop days, calculated as follows:

Labor Hours / Job Hrs/Day = Labor Days

Days to Next

This is the Days to Next setting for this job sequence.

Seq Days

These are the sequence days for this job sequence, calculated as follows:

Setup Days + Labor Days + Days to Next = Seq Days

Buffer Days (important Work Center Capacity setting)

This is the Capacity setting Buffer Days setting for this work center. This is what you consider to be the standard queue days for this work center. This can represent the time it typically takes to start a sequence that is added to a work center. A job typically spends more time in work center queues than it does in actual production.

Link:

Shop Control Guide - Setup - Work Center Capacities

Shop Control Guide - Setup - Work Center Capacities

Job Days

These are the total job days for this sequence, calculated as follows:

Seq Days + Buffer Days = Job Days

Job Hrs/Day (important Work Center Capacity setting)

This is a very important Capacity setting Job Hrs/Day setting for this work center. This value is divided into the Setup Hours and Labor Hours to translate those field values into Setup Days and Labor Days.

Link:

Shop Control Guide - Setup - Work Center Capacities

Shop Control Guide - Setup - Work Center Capacities

Setup Hours

This is the setup time for this job sequence. You can click the down arrow to view the calculation details.

Labor Hours

This is the total process time required to make the Job Qty. It is calculated as follows:

Items/Proc * Hours/Proc * Job Qty = Labor Hours