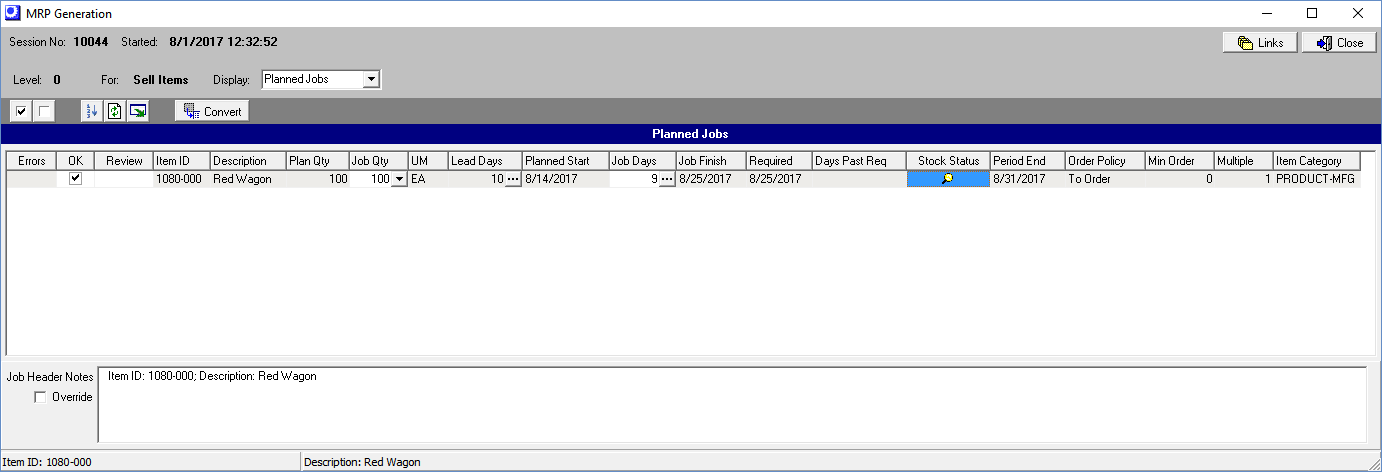

(MRP – MRP - MRP Generation - Planned Jobs)

The screen details presented in the section pertain to all three item types – CTO items, sell items, and subassembly items.

MRP Overview

You must convert all suggested Jobs and POs in an MRP Session

You must convert all suggested Jobs through all levels to meet your current requirements. The planned start dates of your converted Jobs drive the demand for your subassemblies and Purchased items. You must do a complete MRP run of all Jobs and suggested POs within each MRP session to ensure the integrity of your plan.

Item Time to Shipment targets generate sales order line item Required Dates to provide the demand that drives daily MRP generation. Jobs and POs are generated and converted level by level in response to current net demand within item planning periods relative to Reorder Points and Min Order quantities. Job and PO dates are derived and aligned from standard lead times with coordinated system target dates.

Demand Dates |

Supply Dates |

SO Line Required Date |

Job Finish Date |

Job Planned Start Date |

PO Line Expected Date |

React to the firm - MRP Action Windows

Instead of reacting to tentative demand, MRP will only react to firm demand. Each item has its own “action window”, which covers the time it takes to make or buy the item. MRP only reacts to demand within the action window, which is firm demand. Any demand outside the action window is tentative demand that is incomplete and highly likely to change as it firms over time.

Reacting to the firm yields miraculous benefits. Planned supply is always aligned with firm demand, which eliminates the misalignments that are the root cause of shortages, overstocking, and the need for constant job and PO revisions. Each item is planned individually, which eliminates the bullwhip effect from BOM explosions and job linking that amplifies misalignments at lower levels.

Screen Details

Grid Columns

Errors

A red icon displayed in this field indicates that errors exist that prevent this planned job from being converted. You can click the icon to get a listing of the error(s), which can include:

| • | The Item ID is invalid. |

| • | The Item ID is inactive. |

| • | The Item has no BOM. |

| • | This item has not yet been reviewed. |

OK

Select this checkbox to indicate that this planned job has been reviewed. All the OK checkboxes must be selected before planned jobs at this level can be converted into actual jobs.

Review

An icon is visible in this field when the item has a Review Note, which provides a means for conveying special planning instructions for the item. The icon is initially colored red because planned job conversion is not permitted until you acknowledge that the Review Note has been read. To do so, click the icon, read the note text, then click Yes against the Review Completed? prompt. The icon will now be colored green to indicate that the note has been reviewed.

Item ID, Description

These fields identify the manufactured item.

Plan Qty

This is the planned job quantity, established as follows:

| • | For CTO items, this is made equal to the order quantity of the associated sales order line. |

| • | For sell and subassembly items, this is made equal to the item’s Reorder Point or Min Order quantity, whichever is greater. If the item has a Multiple quantity, the Plan Qty is rounded up to the nearest increment divisible by that quantity. |

Job Qty

This will be the quantity assigned to the actual job when the planned job gets converted. By default, it is made equal to the Plan Qty.

CTO Items

With CTO items, the Job Qty can only be the current value, which matches the sales order quantity, or zero, which postpones job conversion. Job conversion should be postponed s when BOM customization details are not yet fully completed. To set the value to zero, click the button in this field.

Sell & Sub Items

With sell and subassembly items, this is the minimum quantity needed to meet current requirements. The Job Qty is normally not subject to change, but if for some reason you wish to increase it, you can enter a larger amount.

WARNING: Do not decrease the Job Qty, which serves no purpose. If you do so, MRP will immediately generate another planned job for the shortfall amount in the next MRP session.

Split Job Option

If you wish to split the planned job into two or more planned jobs, you can do so by clicking the button in this field to launch the Split Job screen. Jobs are typically split to accommodate a capacity limitation associated with a particular machine or job resource.

In the Split Job screen you must allocate the Job Qty amount to two or more quantities. After saving your entries, the Job Qty field is displayed in yellow to indicate that the job has been split.

UM

This field displays the item’s stocking unit of measure.

Lead Days

This is the items Lead Days allocation, which is displayed for reference. You can click the button in this field to launch the Lead Days Inquiry, which shows the to-order components that contribute to the calculated Lead Days amount.

Planned Start

This will be the Planned Start date for the actual job. It is assigned by the program as follows, depending on the type of item.

CTO Items

The master schedule dates for jobs associated with CTO items are established as follows:

| • | If there is a sufficient number of days prior to the sales order line Required date to accommodate the item’s Lead Days and Job Days allocations, the planned job is backward scheduled from the Required date as follows: |

| o | The Job Finish date is made equal to the Required date. The job Planned Start date is backward scheduled from the Job Finish date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. |

| • | If the number of days prior to the sales order line Required date is not sufficient to accommodate the item’s Lead Days and Job Days allocations, the planned job is forward scheduled from the current date as follows: |

| o | The Planned Start date is forward scheduled from the current date by the item’s Lead Days allocation. The Job Finish date is forward scheduled from the Planned Start date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. The result will be a Job Finish date that is later than the Required date. |

Sell & Sub Items

The master schedule dates for jobs associated with sell and subassembly items are established as follows:

| • | If there is a sufficient number of days prior to the Required date to accommodate the item’s Lead Days and Job Days allocations, the planned job is backward scheduled from the Required date as follows: |

| o | The Job Finish date is made equal to the Required date. The job Planned Start date is backward scheduled from the Job Finish date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. |

| • | If the number of days prior to the Required date is not sufficient to accommodate the item’s Lead Days and Job Days allocations, the planned job is forward scheduled from the current date as follows: |

| o | The Planned Start date is forward scheduled from the current date by the item’s Lead Days allocation. The Job Finish date is forward scheduled from the Planned Start date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. The result will be a Job Finish date that is later than the Required date. |

Job Days

This is the number of shop days allocated by MRP for production, which determines the spread between the Planned Start and Job Finish date. It defaults to the item’s Job Days allocation.

Reducing the Job Days allocation

The item’s Job Days amount is based on making the Run Size, which represents a typical larger-size job quantity for the item. The allocation is purposely biased towards larger job quantities so that it is sufficient to cover the entire range of job quantities, large or small, that is likely to occur.

NOTE: It is often best to leave the Job Days as a fixed allocation that does not vary from job to job. This assures consistency of dates from one MRP run to another. Job priority automatically adjusts to reflect variations in job quantities.

One optional exception to this guideline is when a planned job quantity is significantly smaller than the item’s Run Size. In that case you can reduce the Job Days allocation to reflect the shorter production time associated with the smaller job quantity. Doing so will move up the Job Finish date, which enables you to manually move up associated sales order Required date(s) for earlier shipment.

To adjust the Job Days allocation, click the button in the Job Days field to launch the Change Job Days screen. In the Planned Job Values panel, enter the new Job Days amount. You can click the button in the entry field to launch the Job Days Inquiry, which calculates a theoretical Job Days amount by applying the job quantity to the item’s current routing and work center settings.

NOTE: When the Job Days amount has been reduced, it is displayed in bold blue.

Link:

Job Finish

This will be the Job Finish date for the actual job. It is assigned by the program as follows, depending on the type of item, and can only be changed by reducing the Job Days allocation.

CTO Items

The master schedule dates for jobs associated with CTO items are established as follows:

| • | If there is a sufficient number of days prior to the sales order line Required date to accommodate the item’s Lead Days and Job Days allocations, the planned job is backward scheduled from the Required date as follows: |

| o | The Job Finish date is made equal to the Required date. The job Planned Start date is backward scheduled from the Job Finish date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. |

| • | If the number of days prior to the sales order line Required date is not sufficient to accommodate the item’s Lead Days and Job Days allocations, the planned job is forward scheduled from the current date as follows: |

| o | The Planned Start date is forward scheduled from the current date by the item’s Lead Days allocation. The Job Finish date is forward scheduled from the Planned Start date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. The result will be a Job Finish date that is later than the Required date. |

Sell & Sub Items

The master schedule dates for jobs associated with sell and subassembly items are established as follows:

| • | If there is a sufficient number of days prior to the Required date to accommodate the item’s Lead Days and Job Days allocations, the planned job is backward scheduled from the Required date as follows: |

| o | The Job Finish date is made equal to the Required date. The job Planned Start date is backward scheduled from the Job Finish date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. |

| • | If the number of days prior to the Required date is not sufficient to accommodate the item’s Lead Days and Job Days allocations, the planned job is forward scheduled from the current date as follows: |

| o | The Planned Start date is forward scheduled from the current date by the item’s Lead Days allocation. The Job Finish date is forward scheduled from the Planned Start date by the item’s Job Days allocation, skipping over any non-shop days that are encountered. The result will be a Job Finish date that is later than the Required date. |

Required

This is the planned job’s Required date, which is established as follows:

CTO Items

With CTO items the Required date is made equal to the associated sales order line’s Required date.

Sell & Subassembly Items

With sell and subassembly items the planned job’s Required date is established as follows:

• For all order policies, the Required date is made equal to the earliest date within the item’s planning period when projected stock goes negative.

NOTE: This is the expected behavior for To Order order policy items.

Order Policy = Demand Driven or Manual Reorder Point (Stocking Policies)

| • | If projected stock within the item's planning period is below the reorder point and does not go negative, the Required date is forward scheduled by the item's Replenish Time (Lead Days + Job Days + .MRP Interval + Non-Shop Days). |

NOTE: The goal of demand driven stocking is to trigger a new Job with enough time to replenish inventory prior to running out of stock. Ideally, you will be drawing near down closer to zero by the end of the planning period. This helps keep our stocking levels lean and aligned with your actual supply. If your actual usage exceeds your projected supply, the required date will be pegged to the date the projected stock goes negative.

Days Past Req

If the planned Job Finish date is past its Required date, this is the number of shop days between the two dates. This is for reference only.

What does it mean?

A value in this field means that the job will initially be scheduled late relative to its Required date. This gives the job a higher Priority in work center queues within the Shop Control Panel, which helps the job get back on schedule during actual production. A Days Past Req condition is typically caused by these reasons:

| • | A sales order line Required date was manually moved up and is no longer synchronized with MRP. The remedy for this is to change the sales order line Required date to be equal to the Job Finish date. |

| • | Actual demand exceeded forecasted demand for an item with a Reorder Point, resulting in a projected shortage. There is no corrective remedy when this occurs. |

SO No

This field is only visible against CTO items. It displays the sales order number associated with this planned job.

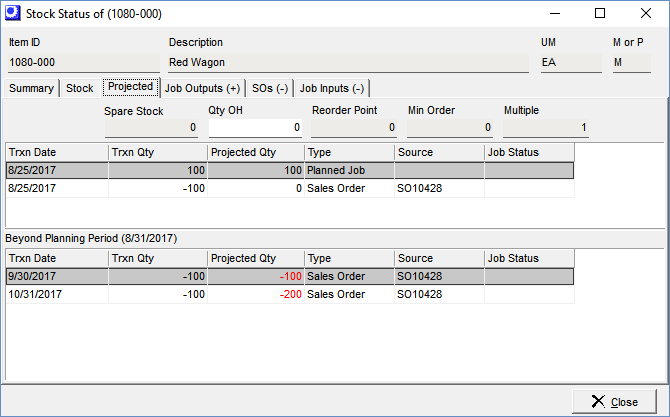

Stock Status

You can click this icon to open the Projected tab of the Stock Status inquiry within which you can view the item’s supply and demand details.

Link:

A yellow icon indicates demand beyond the planning period

When the icon is yellow in color, it means that demand events exist beyond the planning Period End date. This is for information only and requires no additional action at this time.

Period End

This is the item’s planning Period End date. The item’s Planning Period is the total number of calendar days allocated by MRP for assessing net demand. It consists of the following elements, which can be viewed by clicking the down arrow in this field:

MRP Interval + Lead Days + Job Days + Non-Shop Days + Extra Shop Days = Planning Period

The Non-Shop Days accounts for non-shop days such as weekends when the shop is not in production. The Extra Shop Days are extra planning period shop days specified in MRP Defaults.

How is it used?

MRP only generates a planned job when an item’s required date is within its planning period, which is the “action window.” Any requirements outside the action window will be responded to in a future MRP run.

How to expand the planning period

Our recommendation is to keep a tight planning period action window (especially for items you Sell) as this reduces the errors and conflicts introduced by premature action on tentative demand. You can expand your planning period action window in the following ways:

Sell Items (Level 0 and CTO) - Increase the MRP Interval in MRP - MRP Setup - MRP Interval. You can increase the MRP Interval up to a max of 7 shop days.

Subassembly Jobs - Increase the Extra Days for Lower Level M Items in MRP - MRP Setup - MRP Defaults - Item Planning Period - Replenish Time + Extra Days

Purchased Items - Increase the Extra Days for P Items in MRP - MRP Setup - MRP Defaults - Item Planning Period - Replenish Time + Extra Days

Order Policy, Min Order, Multiple

These read-only fields display the item’s current MRP settings for reference purposes.

NOTE: These fields are not visible against CTO items

Item Category

This read-only field is provided for reference and sorting purposes.

Job Type

This field is only visible when two or more job types are defined in the Job Types screen. The default Job Type is automatically assigned, but can be changed if desired.

Lower Panel

Job Header Notes

If you wish to pass special instructions or comments to the actual job, you can enter freeform text in this panel that will populate the header Job Notes when the planned job gets converted. The Item ID and Description are inserted by default.

Override

This checkbox is automatically selected when the default Job Header Notes have been edited, which helps you discern standard notes from customized notes.